Engineering Services

Providing You With The Most Insightful Data.

Let's Work Together

Services can be performed at your facilities or one of our offices.

You can leverage our world-class engineering expertise at any stage of your product development. We provide flexibility and quick implementation or deployment of our technologies, we have a team of Applications Engineers and a pool of equipment dedicated to our engineering services, for work on-site at your facilities or performed at our offices around the country.

Trilion Engineering Services

Material Testing

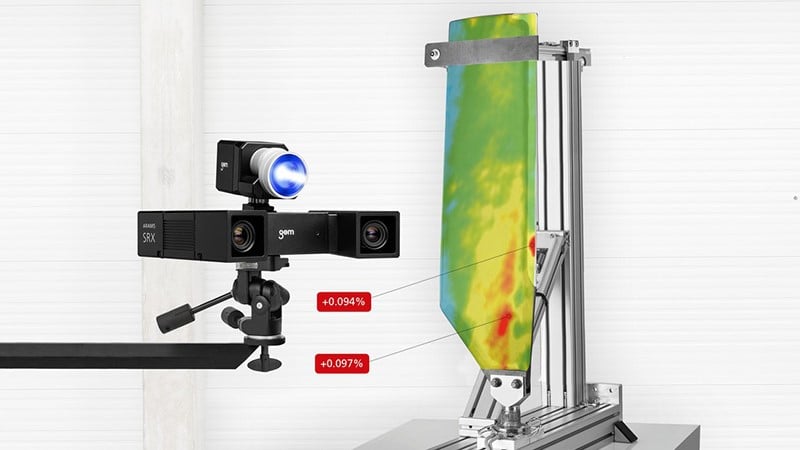

ARAMIS 3D-DIC is the ideal tool for measuring material properties to most ASTM and ISO standards.

Component Testing

Full-field component testing that measures all points for direct FEM comparison to the real multi-material, structural response

Structural Testing

ARAMIS Optical Strain allows for a holistic understanding of the structural response of your test structures.

High-Speed Testing

ARAMIS 3D High-Speed combines high-speed cameras with our powerful ZEISS Inspect software to measure components at any speed, for high strain rate materials testing, vibration analysis, and impact testing.

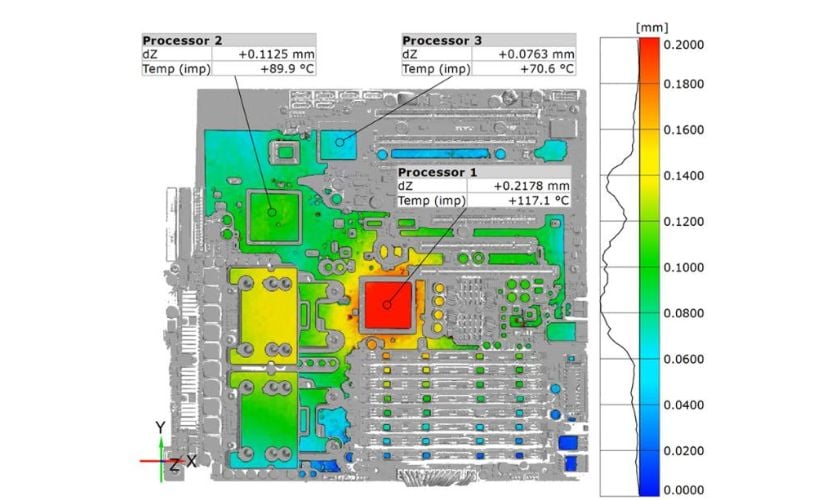

ARAMIS Thermography

ARAMIS can be synchronized with a thermal imaging camera to capture temperature information. The temperature data can be imported, aligned, and mapped in 3D coordinates directly to the inspection.

Digital Assembly

For precise fixture alignment and assembly in 6-DOF (degrees of freedom).

Step for Success

Test Program Preparation

○ Develop test methodologies

○ Define test scope and schedule

○ Equipment recommendations

○ Establish experiment technical requirements

Test Program

○ Test article preparation

○ Methodology validation

○ On-site data acquisition

○ Integration with test methods

○ Preliminary data review

Test Data Analysis

○ Detailed data analysis

○ Test campaign report preparation

○ Data export

○ Data review

Discover Our Technologies

ARAMIS OPTICAL STRAIN

Have our engineers do your testing for you. Providing critical data such as full-field optical strain, 3D displacement, and vibration analysis with ease.

Learn More about ARAMIS

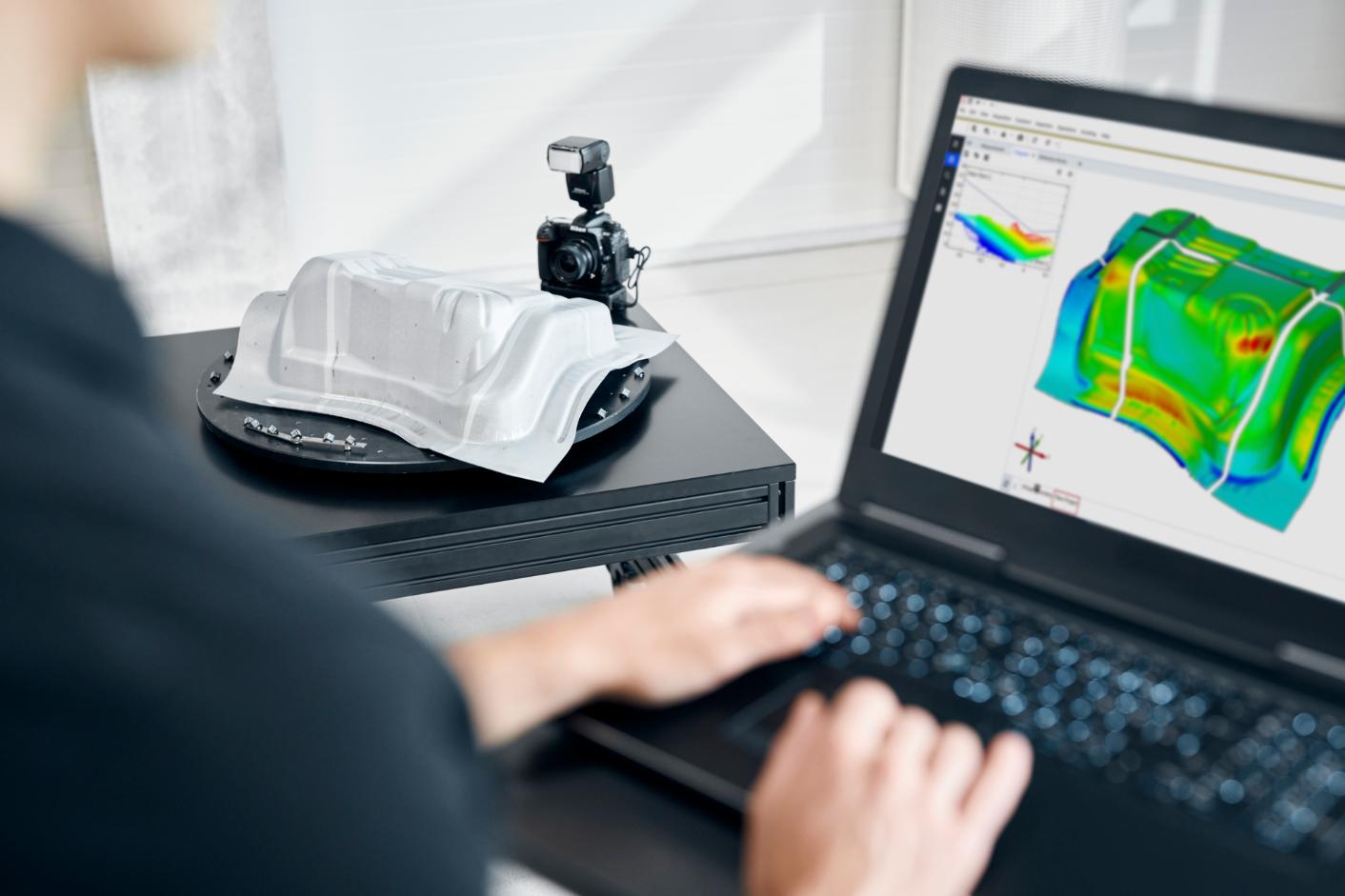

ATOS 3D SCANNING

ATOS sensors are designed as flexible 3D scanners for complex measuring and inspection tasks in different industries. We are happy to scan any objects for our customers.

TRITOP Optical CMM

An optical, mobile, measurement system, which accurately defines the 3D coordinates of object points at quasi-static conditions.

Learn about TRITOP

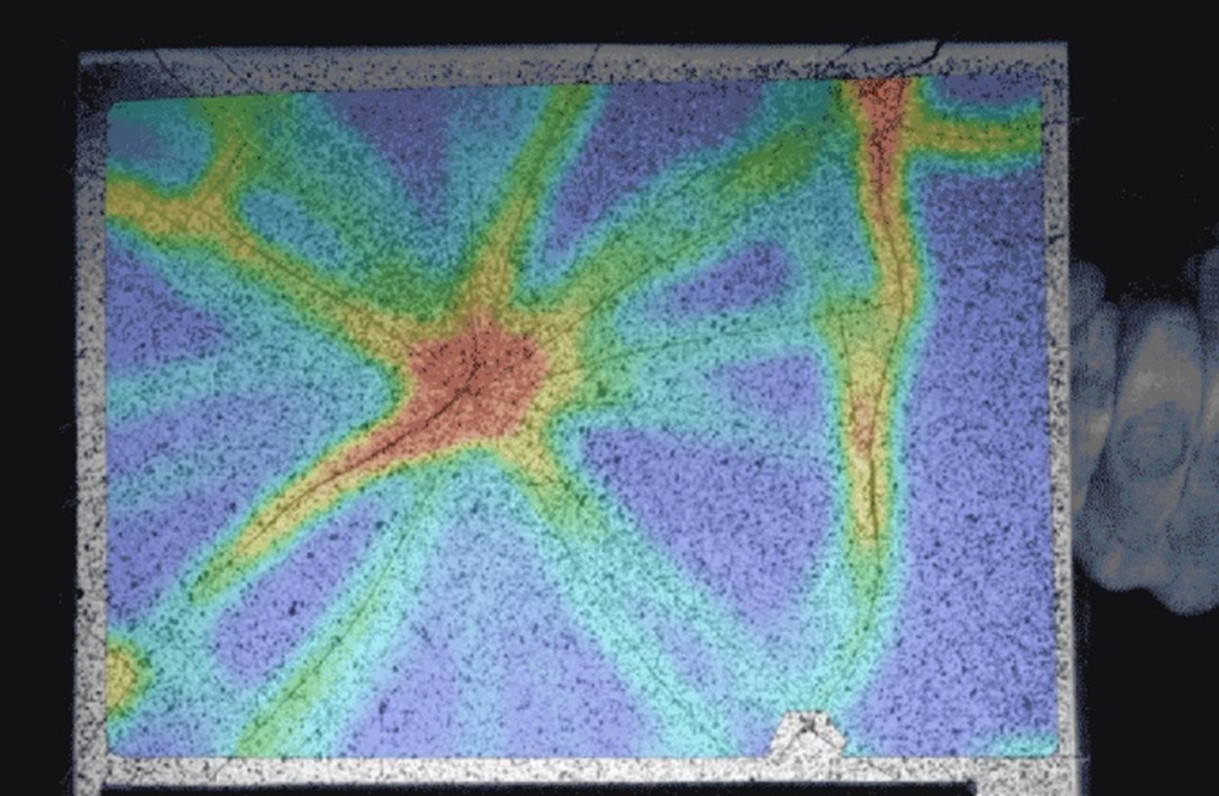

ARGUS OPTICAL FORMING ANALYSIS

We can come & detect critical deformation areas of strain & deformation on sheet metal, help with material formability, optimize operations, & solve forming problems.

Learn about ARGUS

LASER PATTERNING

Having trouble chemical etching? No worries, we can come laser etch for you. Laser etching provides a safe, environmentally clean, more accurate ARGUS pattern on any material.

About LASER ETCHING

We Also Offer

System rental

If you don't have the budget for a system or only need to use our system for a one-time application. Renting one of our systems is the perfect option for you! Renting gives you the flexibility to always have the perfected system for your specific test.

RENT-TO-OWN (LONG TERM LEASE)

If you need more purchasing flexibility, we have long-term rental programs which let you apply the entirety of every payment to the purchase balance. Ask your Technical Account Manager about our rent-to-own program.

"Any university that is not teaching DIC is in the dark ages."

"If you invest the time, money, and hardware then you need to do the other 10% and be around people with the seat time and be in the atmosphere where you can draw from the experiences of the seasoned user."

"The full-field ARAMIS Optical Strain data is intuitively understood. We now analyze the full-field data, and there are no arguments about the results. It is intuitively obvious what is occurring to our structures."

"You acquired an ARAMIS system for composite buckling studies, what are you using it for now?" He responded, "Everything"

Let's discuss your Test!

Let's ensure our services perfectly fit your needs by setting up a discovery call.