Biomechanics, Biomedical, Bone Implant, Cosmetic, Dental, Athletic Apparel Testing

Measurements that are personal!

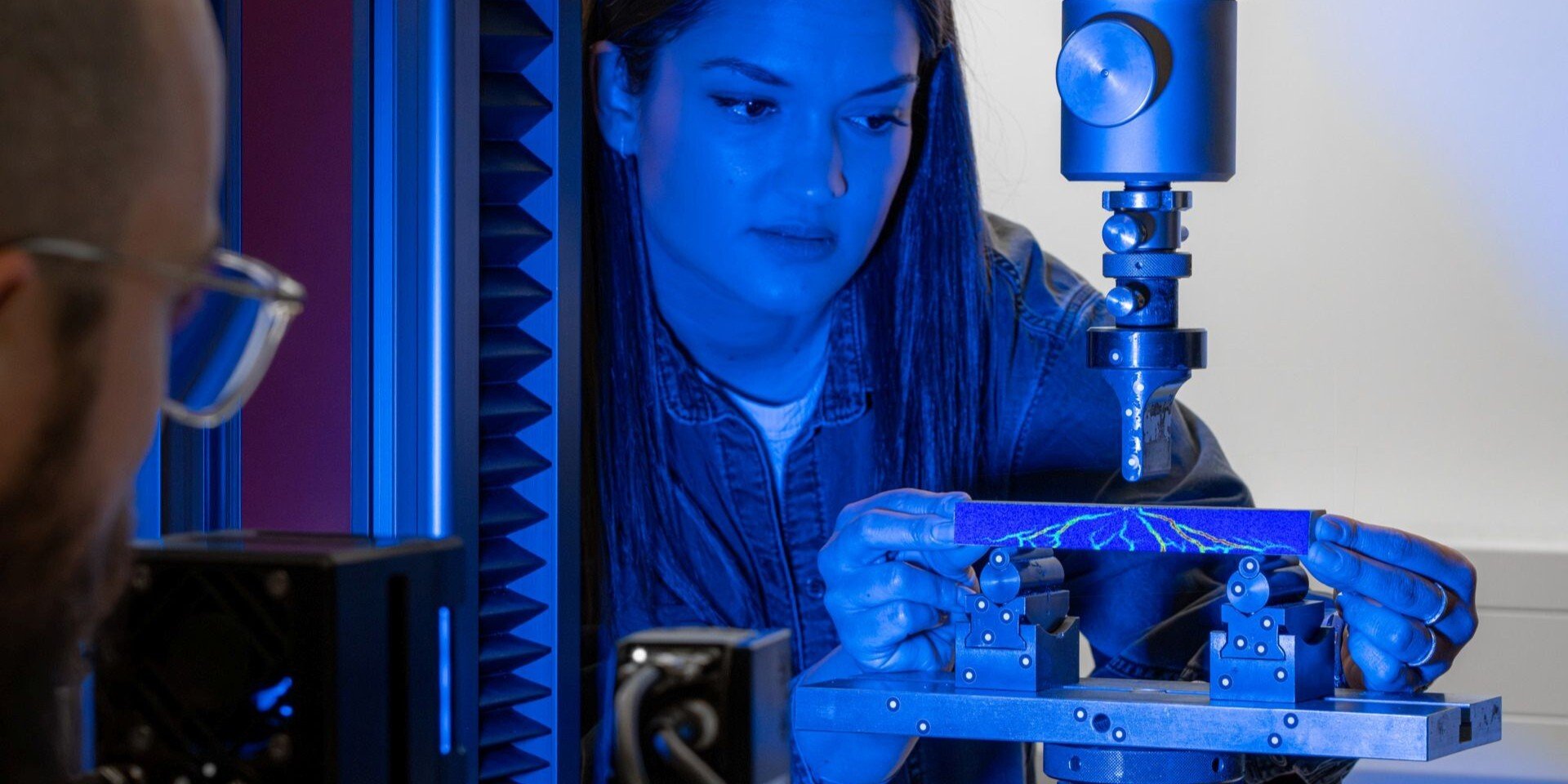

BIOMECHANICS & MEDICAL DEVICES

Optical 3D metrology has been established in the biomechanics & medical device industry for dynamic analysis of everything from implants and prostheses to bones, tendons, and ligaments. During strain, load, and fatigue tests, the mechanical properties of biomaterials and their behavior are analyzed. Major organizations in bioengineering, medical device manufacturing, medical research, and even athletic apparel use ZEISS systems to analyze new materials, and to develop innovative products from the new materials.

Athletic Apparel & Footwear

Trilion supports most major players in the athletic equipment, apparel, and footwear industries with our systems and services. Quasi-static ARAMIS 3D systems analyze innovative materials. High-Speed ARAMIS 3D systems capture and analyze athlete movement. No matter the system, ZEISS tools are used to perfectly inform sports engineers and their design of game-changing apparel and footwear. Examples include motion capture and dynamic analysis of athlete movement in:

- Footwear

- Sports Bras

- Athletic Tights

- And more!

Biomechanics & Bone Implants

Trilion supports companies and research groups in the biomechanics and bone-implant industries with our ARAMIS 3D systems and our consulting services. Examples of standard applications are:

- Micromotion measurements between bones and implant

- Joint dynamics and motion capture

- Strain quantification on bones and implants

- Tendon repair studies

- Impact and dynamic tests on prosthetics

Cosmetics

While beauty is in the eye of the beholder, success in the beauty industry is in the hands of researchers using ARAMIS 3D systems. ZEISS products provide the ability to quantify the impact of products and procedures. Examples of standards applications are:

- Skin elasticity (residual strain)

- Product effectiveness quantification

- Plastic surgery

- Skin changes: plumping and lift (volumetric surface comparison)

- Botox quantification and effective life

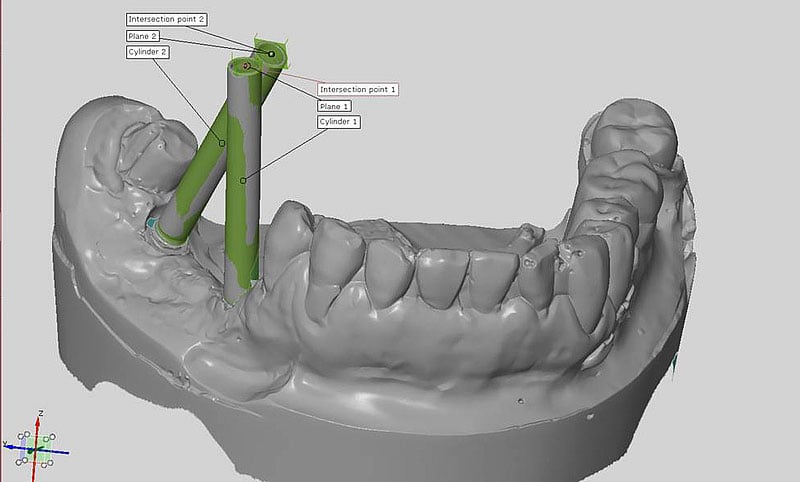

Dental & Orthodontics

Both research and practice of dentistry benefit from the ZEISS ’s ATOS 3D digitizer. ATOS 3D scan data is precise and can be downstream accurately to enable smooth and seamless integration in CAD software packages and rapid prototyping processes. Examples of use cases are:

- Planning and reporting progress of orthodontic treatment

- Scanning implant models for CAD/CAM process chains

- Calculating implant alignment, shape, dimension, etc.

What Role does Optical Testing play in Knee replacements?

Discover how doctors are using the ARAMIS optical testing system to better understand knee kinematics to improve implant design and alignment to achieve better patient outcomes after total knee arthroplasty.

Content Warning

Do not watch if you are sensitive to seeing blood or cadavers.

Product highlight

Our ARAMIS SRX platform is extremely reliable and was designed with material testing in mind. It's rigid fixed camera base offer unparalleled calibration stability and ease-of-use.

Find out more

1 min read

Moving Quality Upstream: A Smarter Path to Precision

Ben Eisdorfer: Nov 19, 2025

1 min read

WEBINAR: Next-Gen Digital Material Testing: ASTM-Certified Precision

Ben Eisdorfer: Sep 24, 2025

1 min read

Webinar: ZEISS ARAMIS 1, Your Entry Point into 3D Optical Testing

Charles-Olivier Amyot: Jul 7, 2025

Webinar: How to Automate Material Testing and Batch Process Data

March 25, 2024, Virtual

Learn more »Revolutionizing Testing with Optical Strain: Workshop at LIFT

August 6, 2024, Detroit, MI

Learn more »Testing with DIC: Workshop at Stress Engineering Services

August 20, 2024, Cincinnati, OH

Learn more »Want to learn more?

Our team can discuss and demonstrate most of our products and applications virtually to you today!