High-Speed, Ballistic, Crash, Drop, Split Hopkinson Bar, Fracture mechanics Testing

When it's too fast to see, we can still measure it!

ARAMIS 3D High-Speed combines high-speed cameras with the power of the ARAMIS Optical Strain software to measure components at any speed, for high strain rate materials testing, vibration analysis, and impact testing, from thousands to millions of frames per second (fps). Standard ARAMIS high-speed cameras run at 6Kfps and up to 50Kfps, while ultra-high-speed cameras can go up to 5Mfps.

ISO Drop testing (1K-20K fps) helps consumer goods designers test for reliability. Micro-electronics companies use ARAMIS Optical Strain to measure the dynamic behavior of dropped components (6 DOF, acceleration…) and their 3D deformation during impact, based on current industry standards.

Impact & Crash testing (5K-50K fps) from automotive and aerospace crash tests to sports helmets design requires data acquisition in thousands of FPS. Full-field measurements of acceleration, displacement strains, and buckling with ARAMIS High-Speed can rapidly generate meaningful data for engineers without installing any contact sensors.

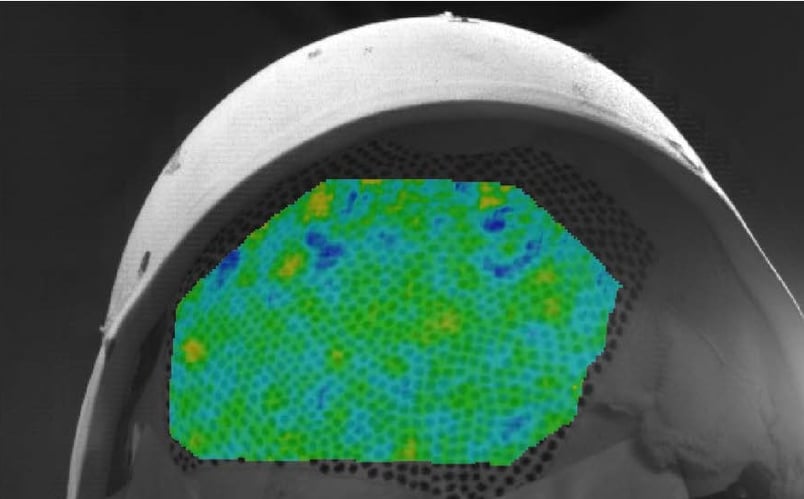

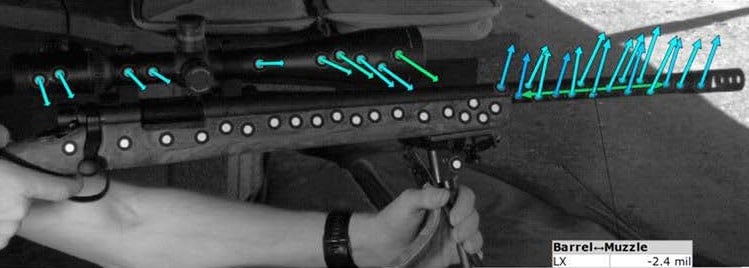

Ballistic & Blast testing (20K-300K fps) has been an early adopter of high-speed imaging. The ARAMIS High-Speed system turns your high-speed cameras into 3D sensors, capable of measuring thousands of data points during highly dynamic events. This picture shows the dynamic response of a military helmet during ballistic impact.

Shock & Brittle Fracture (100K-5M fps), including Split-Hopkinson Bar material testing, requires ultra-high acquisition rates of 100K - 5M fps. In this example, a bullet impacts glass, showing strain concentration during the crack propagations (recorded at 1Mfps).

Back Face Deformation (BFD) Testing

An important consideration for armor ballistic performance is not only to stop the penetrator but also the amount of back face deformation or the deflection of the armor material on the back surface. Even though the armor may defeat a threat projectile, the rear face deformation can cause other damage, for example, blunt force trauma to a person wearing an armored vest or a helmet.

ARAMIS DIC technique was able to track and accurately determine the back face deformation of different helmet structures and order their ballistic performance.

Bomb Blast Effect Testing

ARAMIS has been used many times to measure the response of coupons and structures to explosive loading, from 3 pounds of Pentalite to truck bomb equivalents. High-speed cameras are used to quantify buckling.

Product highlight

Our ARAMIS SRX platform is extremely reliable and was designed with material testing in mind. It's rigid fixed camera base offer unparalleled calibration stability and ease-of-use.

.jpg)

Find out more

1 min read

WEBINAR: Next-Gen Digital Material Testing: ASTM-Certified Precision

Ben Eisdorfer: Sep 24, 2025

1 min read

Webinar: ZEISS ARAMIS 1, Your Entry Point into 3D Optical Testing

Charles-Olivier Amyot: Jul 7, 2025

1 min read

ZEISS ARAMIS 1: The Standard in Entry-Level 3D Optical Testing

Ben Eisdorfer: Jun 13, 2025

Webinar: How to Automate Material Testing and Batch Process Data

March 25, 2024, Virtual

Learn more »Revolutionizing Testing with Optical Strain: Workshop at LIFT

August 6, 2024, Detroit, MI

Learn more »Testing with DIC: Workshop at Stress Engineering Services

August 20, 2024, Cincinnati, OH

Learn more »Want to learn more?

Our team can discuss and demonstrate most of our products and applications virtually to you today!