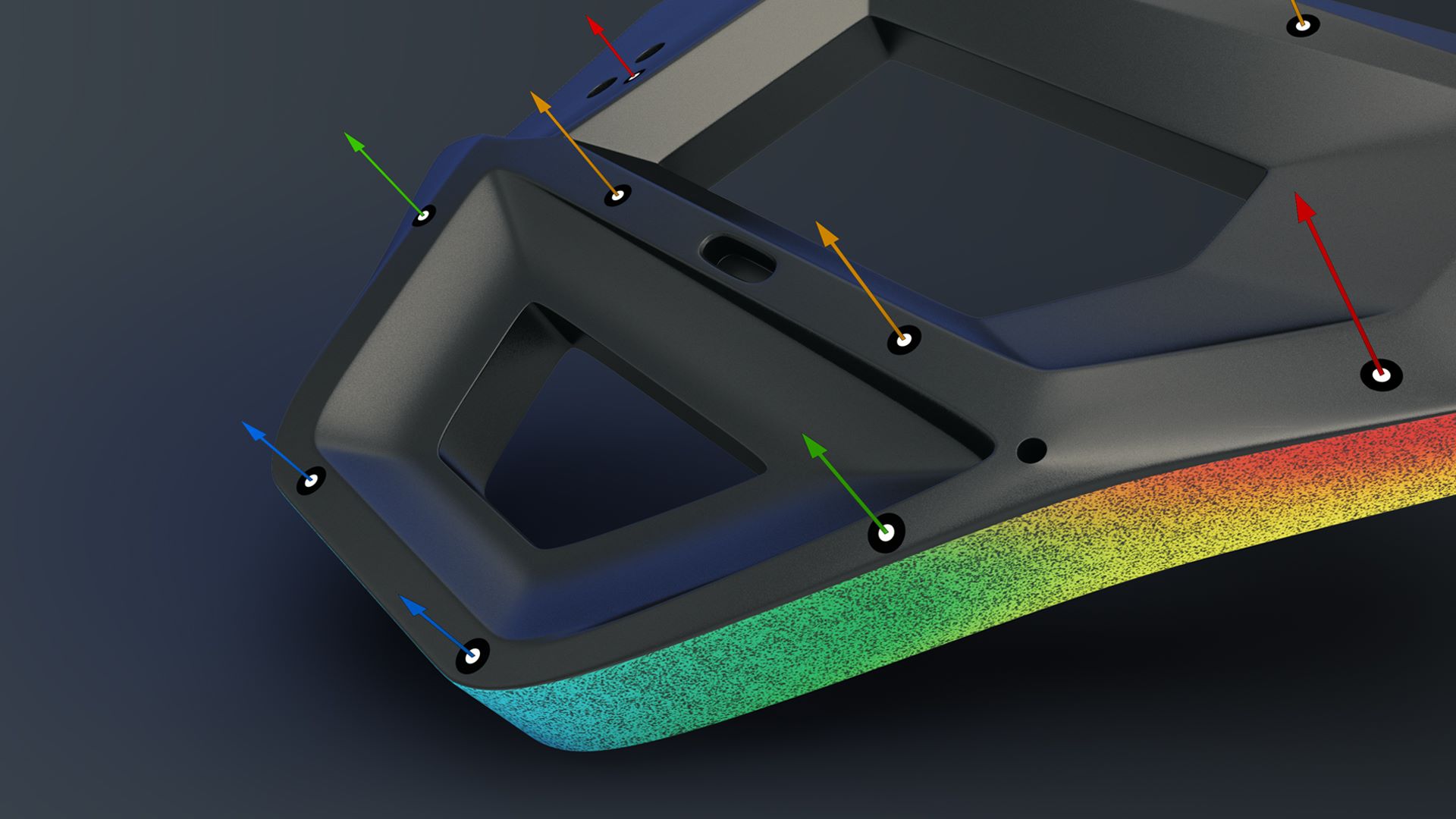

ARAMIS 1 Optical Strain Data, Displacement Data, Vibration Data

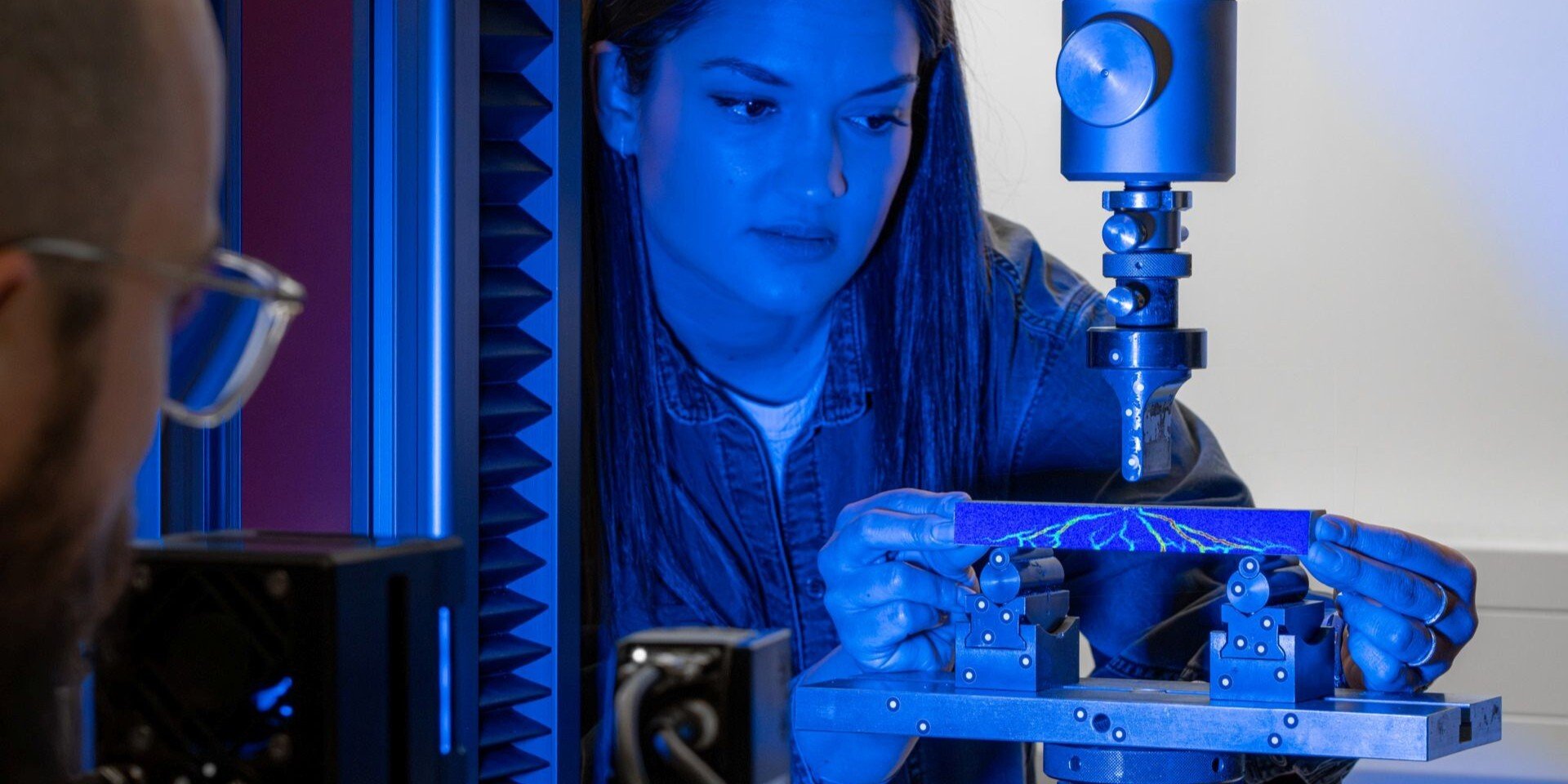

Step into the World of 3D Testing

RESULT BASED

Next-Generation Product Testing And Measurement

Trusted by Fortune 500 companies across a dozen industries.

ZEISS ARAMIS 1

Your Entry Point into 3D Optical Testing

ZEISS ARAMIS 1 is a powerful, entry-level 3D optical measurement system that brings you into the world of non-contact strain and deformation analysis. Ideal for users new to optical testing, ARAMIS 1 uses advanced stereoscopic camera technology to capture full-field strain, displacement, and deformation during quasi-static tests such as tensile, compact tension, and 3- or 4-point bending tests.

Why Choose ARAMIS 1?

- Non-contact, full-field 3D measurement

- Broad measurement ranges for diverse test scenarios

- Built for stability, accuracy, and long-term use

- DAkkS-certified for trusted measurement results

Highlights of ARAMIS 1

All-in-One Optical Sensor

Advanced Measurement Power

The ZEISS ARAMIS 1 is a versatile essential in every test engineer’s toolbox. This comprehensive optical measurement system captures precise 3D data on shape, deformation, and motion, functioning as both an optical strain gauge and a digital alternative to LVDTs.

Non-Contact Measurements

Zero Physical Interference

Leveraging advanced digital camera technology and powerful image processing algorithms, ZEISS ARAMIS 1 captures precise 3D coordinates directly from images or video—eliminating the need for wires, fixtures, or physical sensors.

From Microstrain to Failure

Exceptional Measurement Range

ZEISS ARAMIS 1 delivers outstanding versatility, measuring technical strain from as low as 0.005% up to an impressive 2000%. Its optical sensors also support a broad range of displacement measurements, making it ideal for tests that push materials to their limits.

Proven Reliability

Certified Performance

ZEISS ARAMIS 1 is a precision-engineered optical measurement system, built for dependable operation in demanding test environments. Its performance is certified according to VDI standards and verified through rigorous outbound quality control, ensuring consistent accuracy and robustness you can trust.

Making Your Measurements Digital

Schedule Your Demo Today

Learn MoreIdeal for Material and Component Testing

Tensile Testing with Detailed Strain Analysis

ZEISS ARAMIS 1 offers an extensive strain measurement range, enabling precise analysis of material behavior, including necking and failure, throughout the entire tensile test process.

Biaxial Tension Testing with Full-Field Strain Insight

ZEISS ARAMIS 1 delivers detailed full-field strain data, making it an ideal solution for evaluating biaxial tension tests. Visualize the evolution of deformation in real time and assess the uniformity of strain distribution with precision.

3-Point and 4-Point Bending Tests with High-Resolution Data

ZEISS ARAMIS 1 captures thousands of data points for an in-depth analysis of strain distribution and failure modes during bending tests. With the optional Touch Probe, you can quickly measure and adjust fixture alignment and spacing for optimal test setup.

Precision Testing for Small Components

With measurement volumes ranging from 50 to 500 mm in length, ZEISS ARAMIS 1 is perfectly suited for mechanical and thermo-mechanical testing of small components, offering high-resolution, non-contact data you can rely on.

Flexible Upgrade Options

ZEISS ARAMIS 1 includes all the essentials to begin optical measurements for quasi-static testing of small components, assemblies, and material characterization. For expanded capabilities, a range of compatible hardware and software upgrades are available to enhance your measurement and analysis experience.

ZEISS CORRELATE Pro

ZEISS CORRELATE Pro is built on a fully parametric framework, automatically saving every inspection step to ensure complete traceability of your measurement results. Project templates streamline analysis and reporting, while optional apps expand functionality for specialized measurement tasks.

ZEISS CORRELATE Pro Line

The Pro Line upgrade expands ZEISS CORRELATE with powerful features, including live tracking, ring buffer measurements, & image acquisition triggered by external signals such as force. It also enables the integration of optically tracked touch probes & adapters for greater measurement flexibility.

Touch Probe

The Touch Probe brings together the strengths of optical and tactile measurement. Tracked by the ARAMIS system, it enables precise point-by-point tactile measurements, ideal for part alignment, geometric verification, and quick inspections.

Mobile Case

The mobile case is designed to make transporting your ARAMIS system effortless and secure. It features a ruggedized housing that safeguards the ARAMIS controller and laptop during travel—an ideal complement to the sensor suitcase for on-the-go testing.